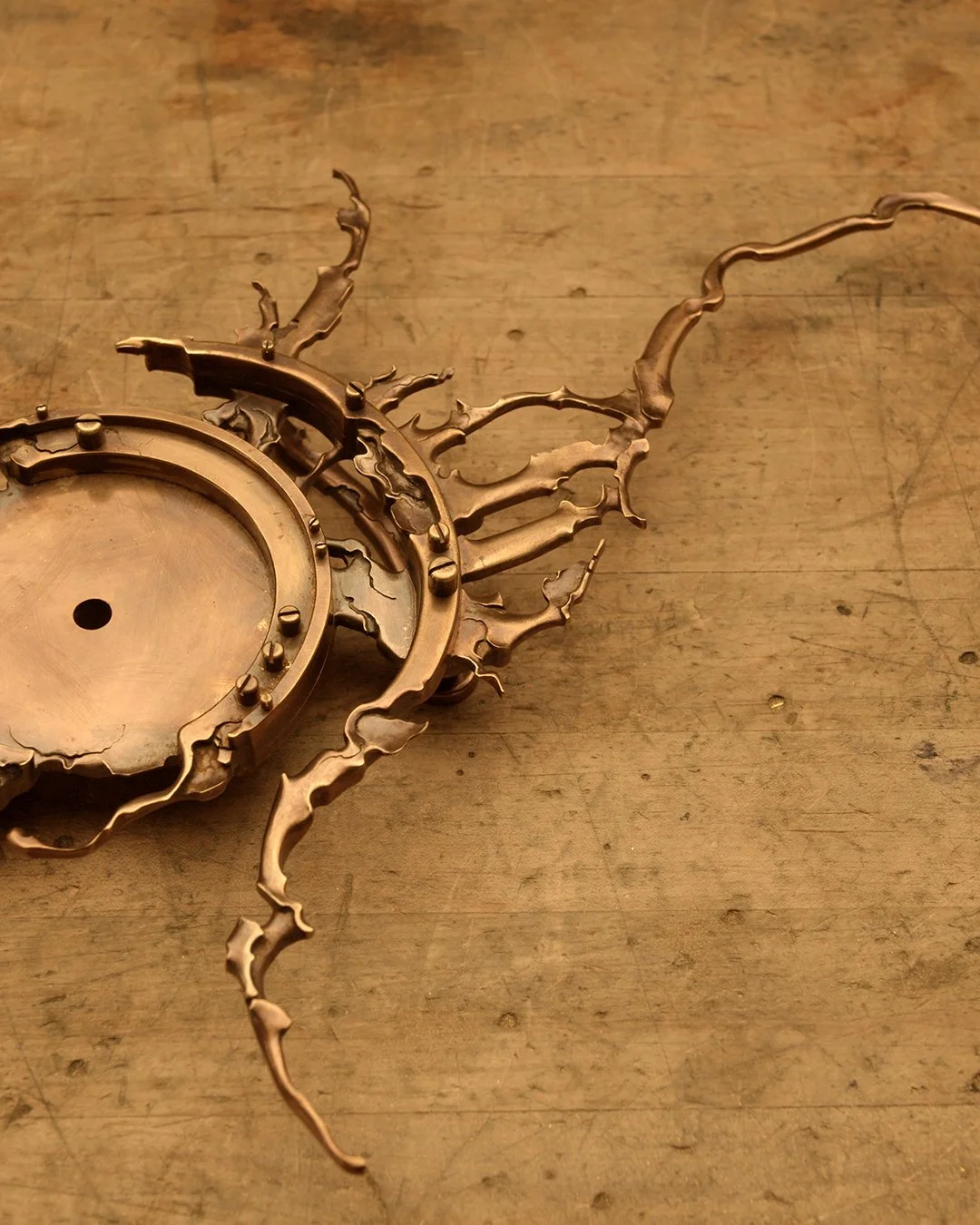

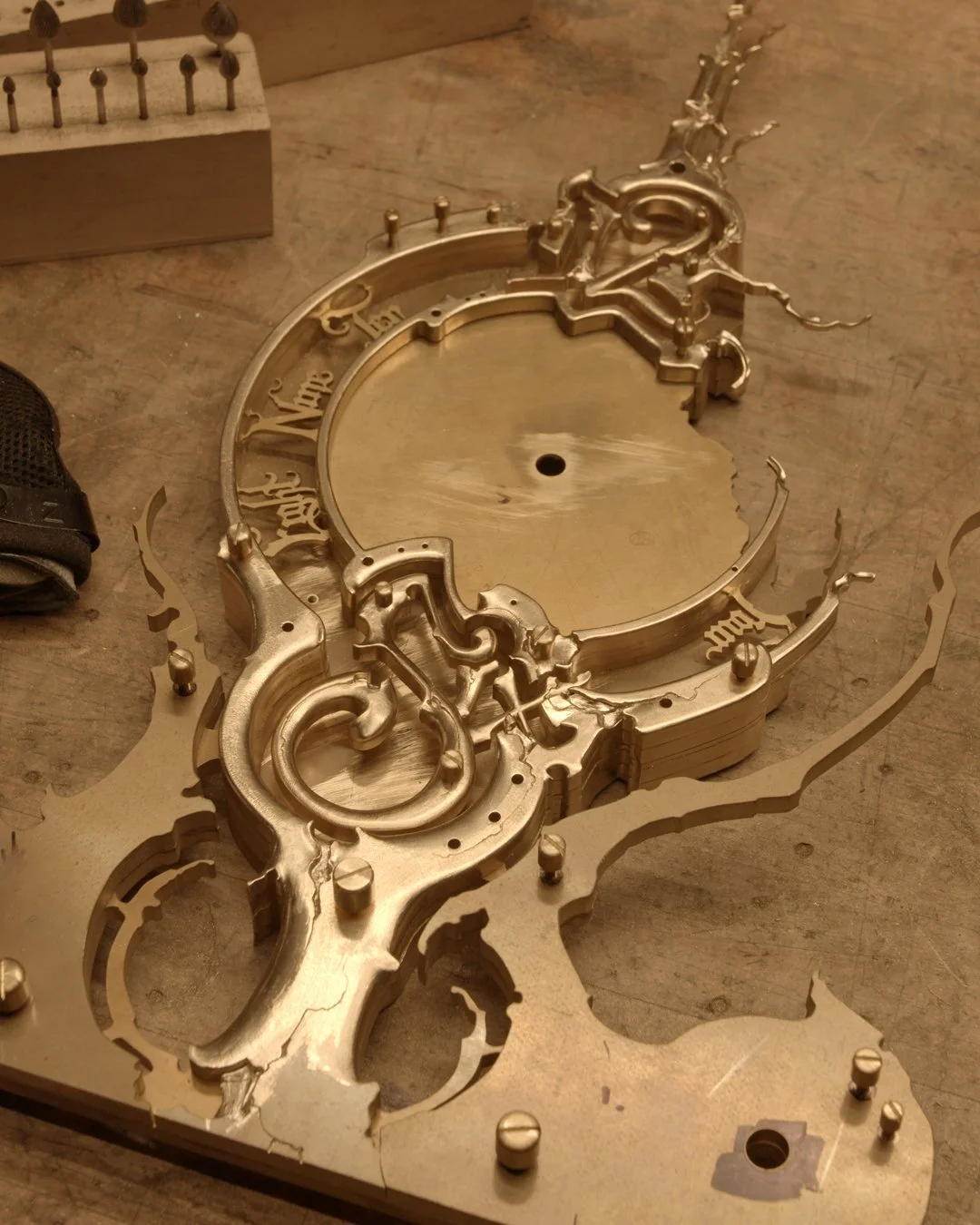

A tellurion is an earth/moon/sun orrery. The sun is in the middle. The earth spins once a day, and also orbits the sun once a year. And the moon orbits the earth.

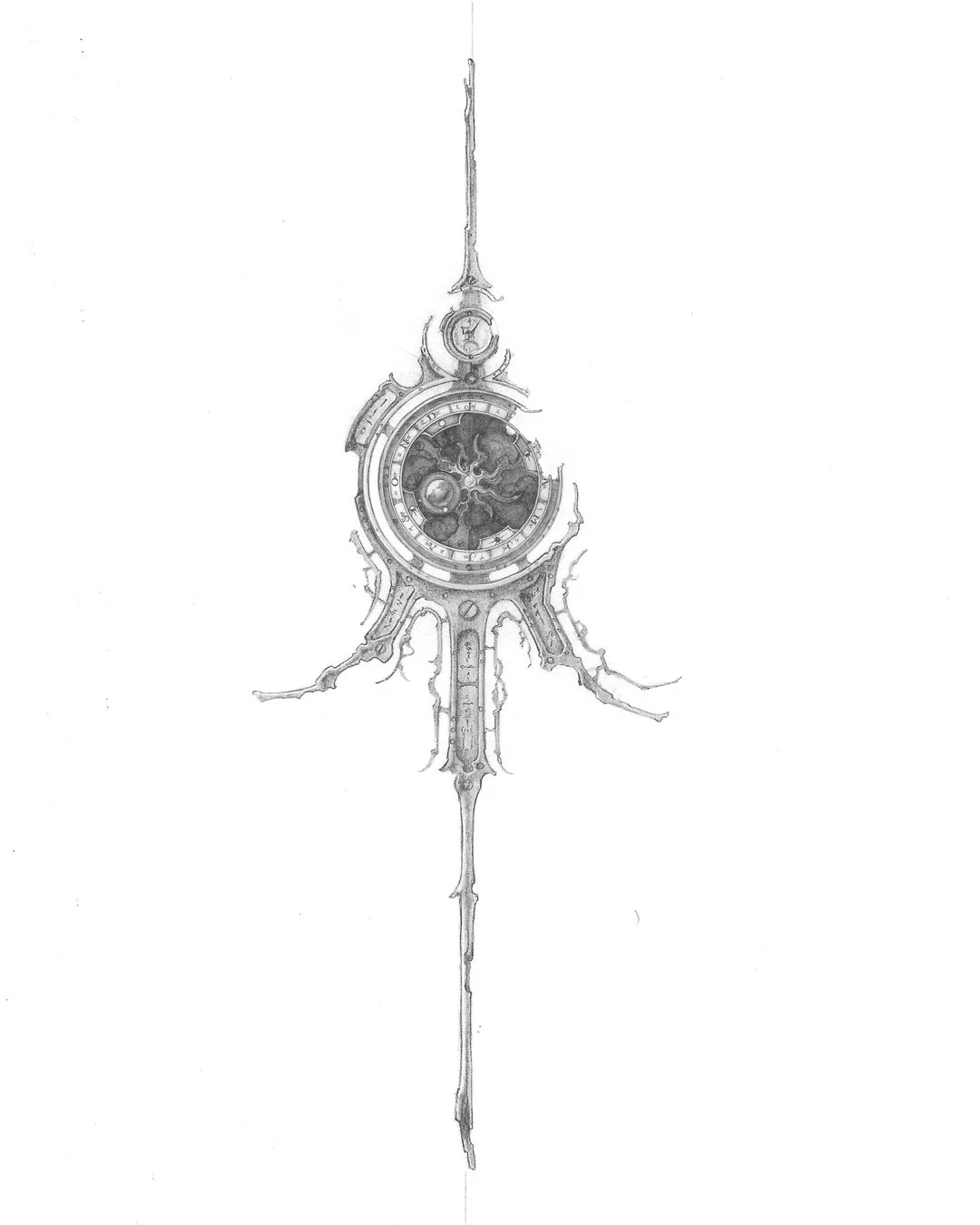

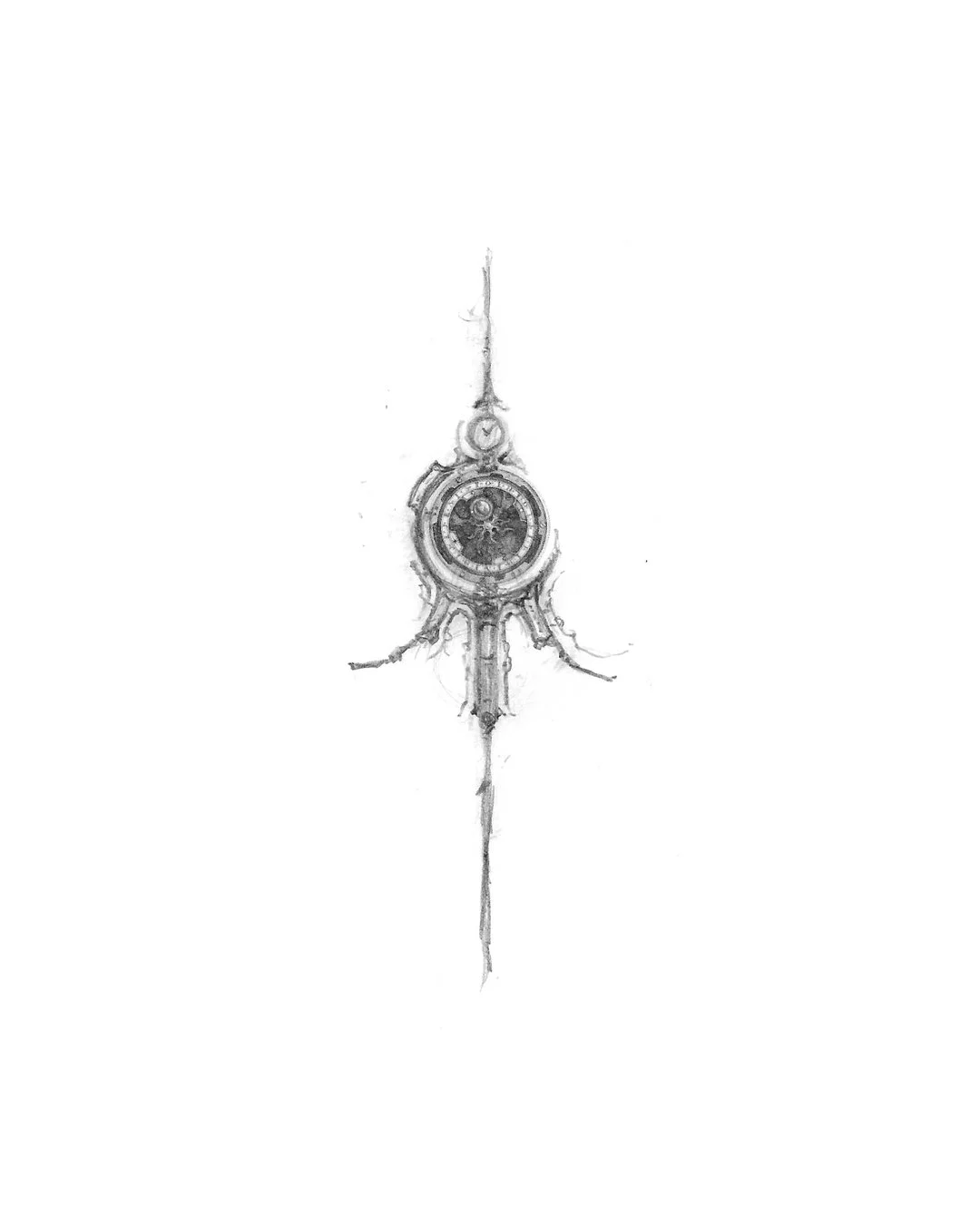

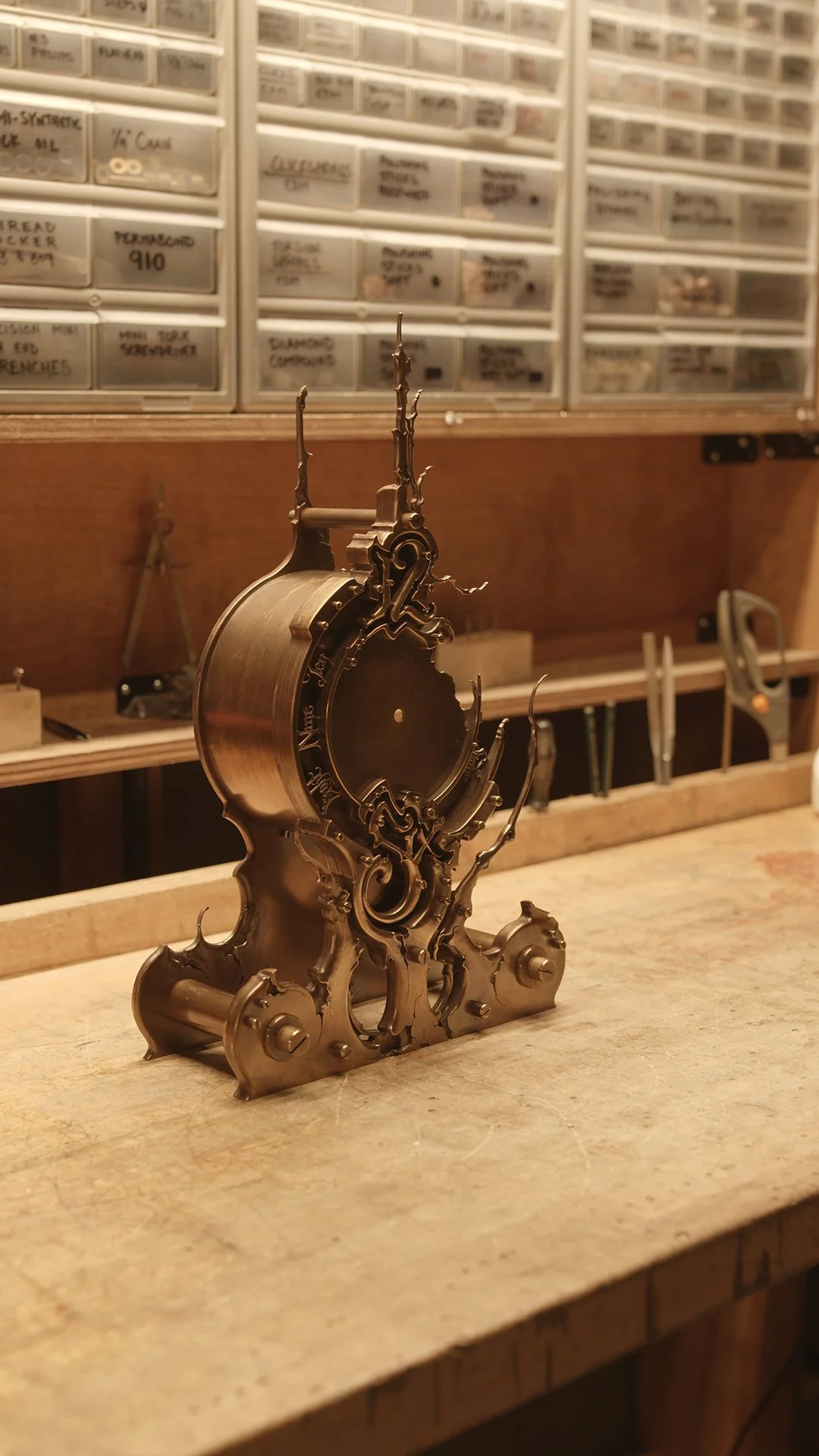

After I worked out the gearing for this complication I wanted to see what it would look like in a clock. The quickest way to do that was to draw up a variation of my “Perpetual No.1” style layout. It visually worked well, but I’ve always wanted to come up with a design dedicated to this new mechanism.

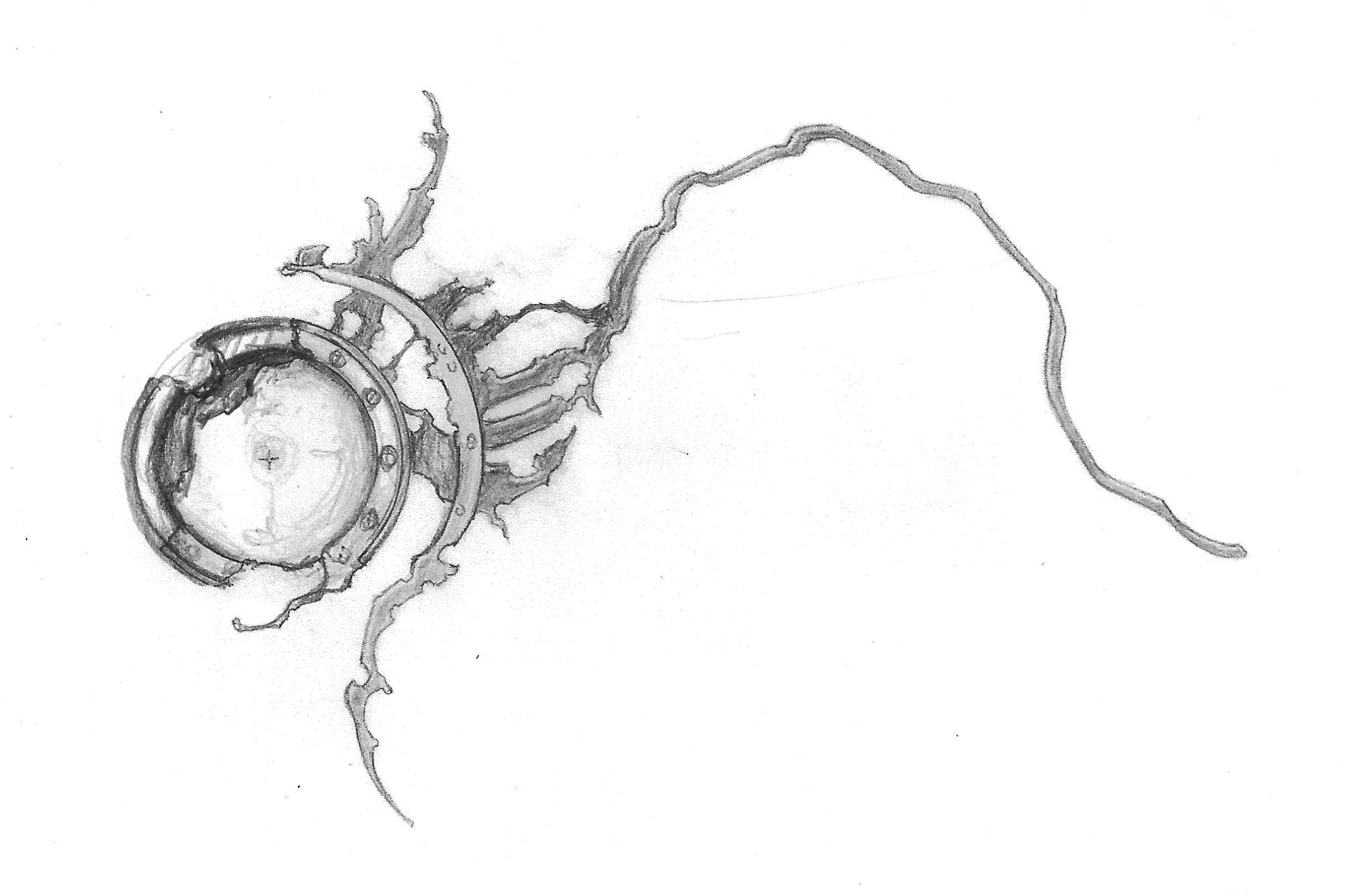

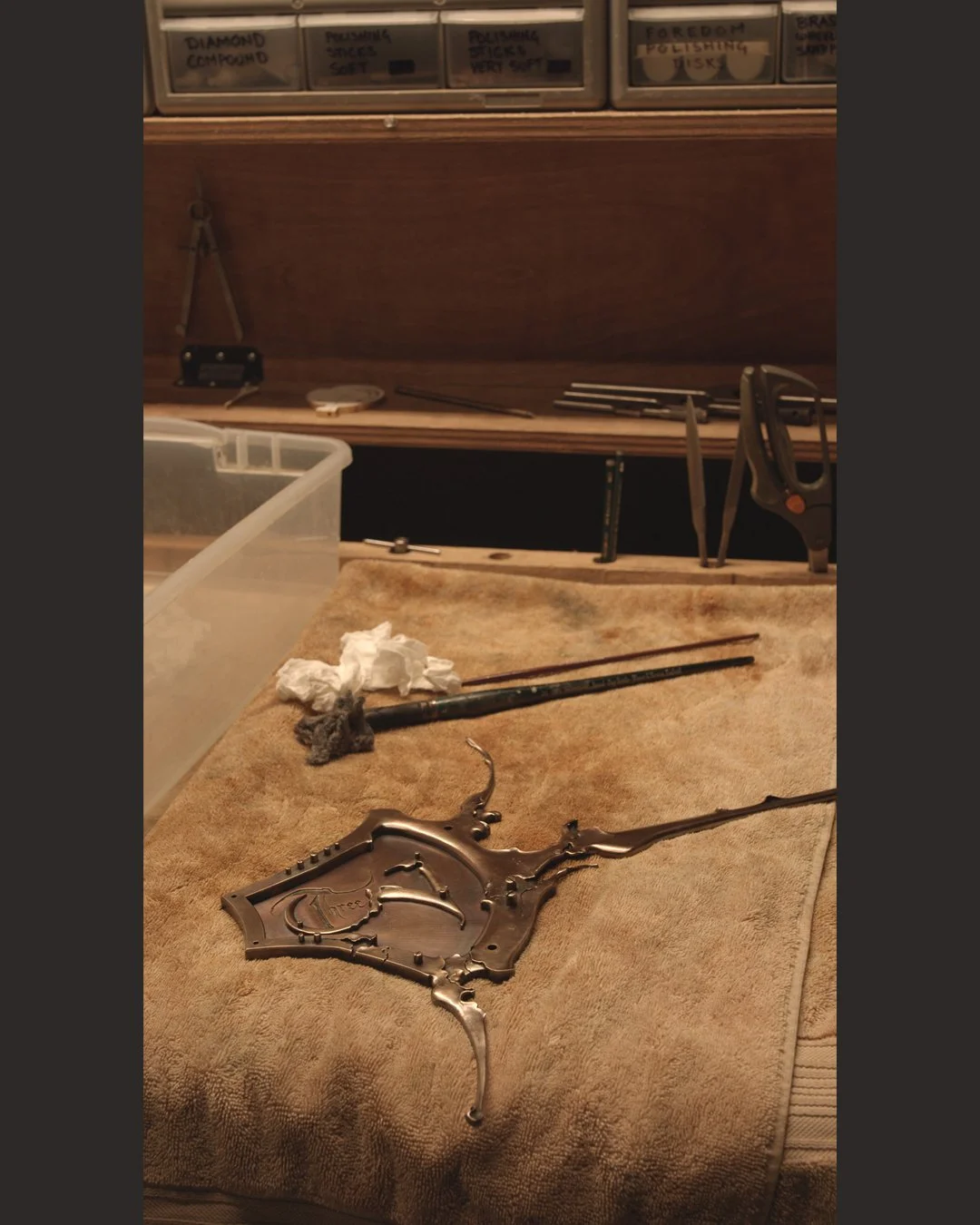

A few days ago I was doing some thumbnails, and stumbled on to this one. I’ve refined it over the last couple days, but I still have to tighten it up, and work out some mechanical things. I really like the way this one is shaping up.

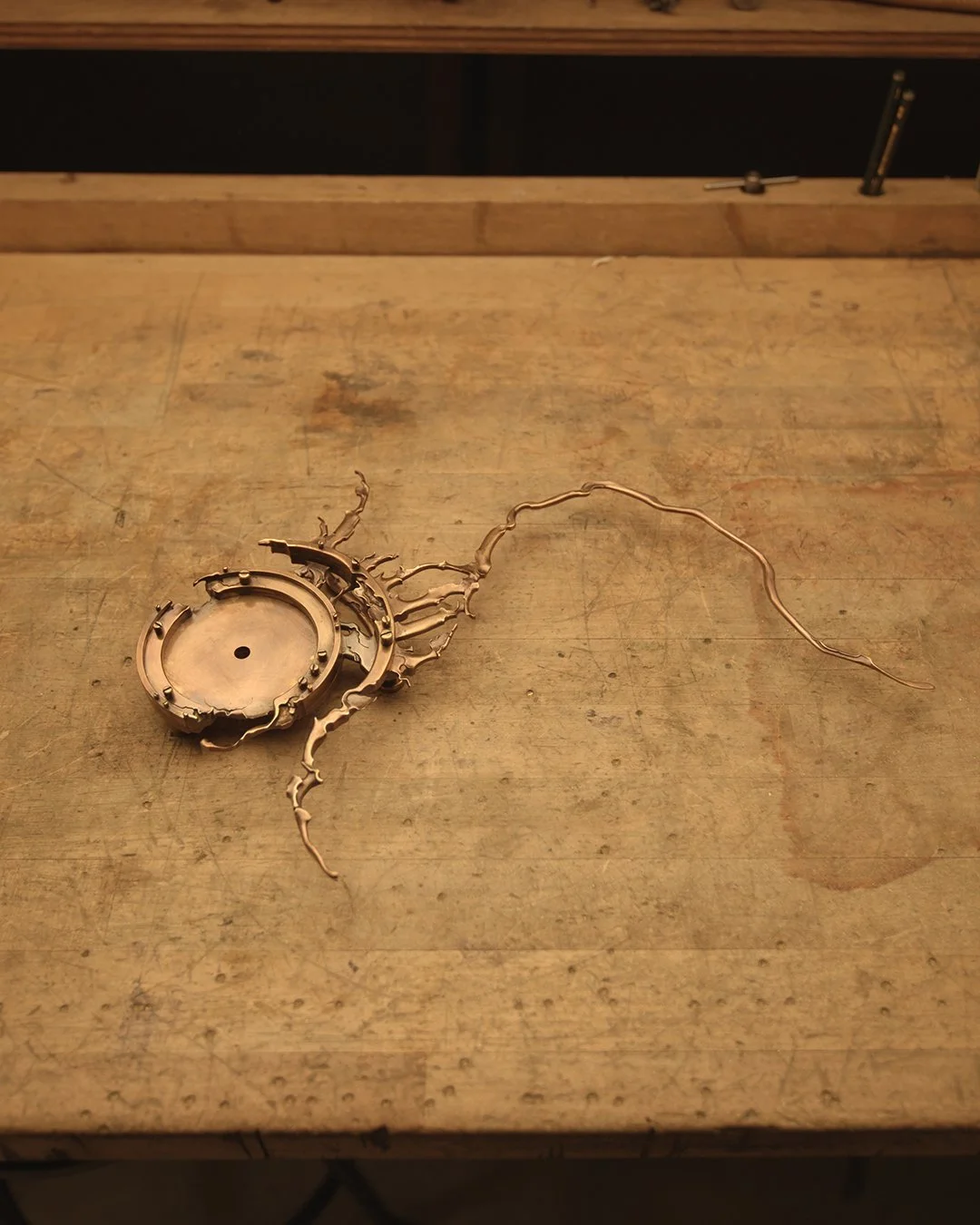

The little dial on top is for the time. If I keep it clean and simple enough, it won’t need to be very big. This allows the tellurion orrery to be the hero of this piece.

I’m going to set this one aside for now and get some mental separation from it.

Creating this one would land in the ‘thousands of hours’ category, so I won’t be able to tackle it anytime soon. However, it is at the top of the stack, prioritized alongside a couple other favorites.