In late 2019, I finished “Perpetual No.1”. As the name indicates, it was my first clock featuring a perpetual calendar complication. In June 2020, I was contacted by a gentleman from Perth, Australia who was interested in commissioning a piece based on the “Perpetual No.1” design. After a thorough back-and-forth with drawings, emails, and phone calls, we arrived at a this beautiful design.

However, work didn’t start right away.

People always speak of the patience it must take for me to create these works. But I would also like to express my gratitude for the patience that my clients have. When I was first contacted for this clock, I had just started work on “The Grasmere Commission”, a nearly two-year project. Then, this piece required over a year to complete and months to properly test and refine. To top it off, there was a three-month delay when I moved my shop to another location. In total, the client had to wait over 3 years to see a finished piece, and by the time, it’s delivered it will be closer to four years.

In 2023, this clock, titled “Perth”, was completed. I believe it was worth the wait.

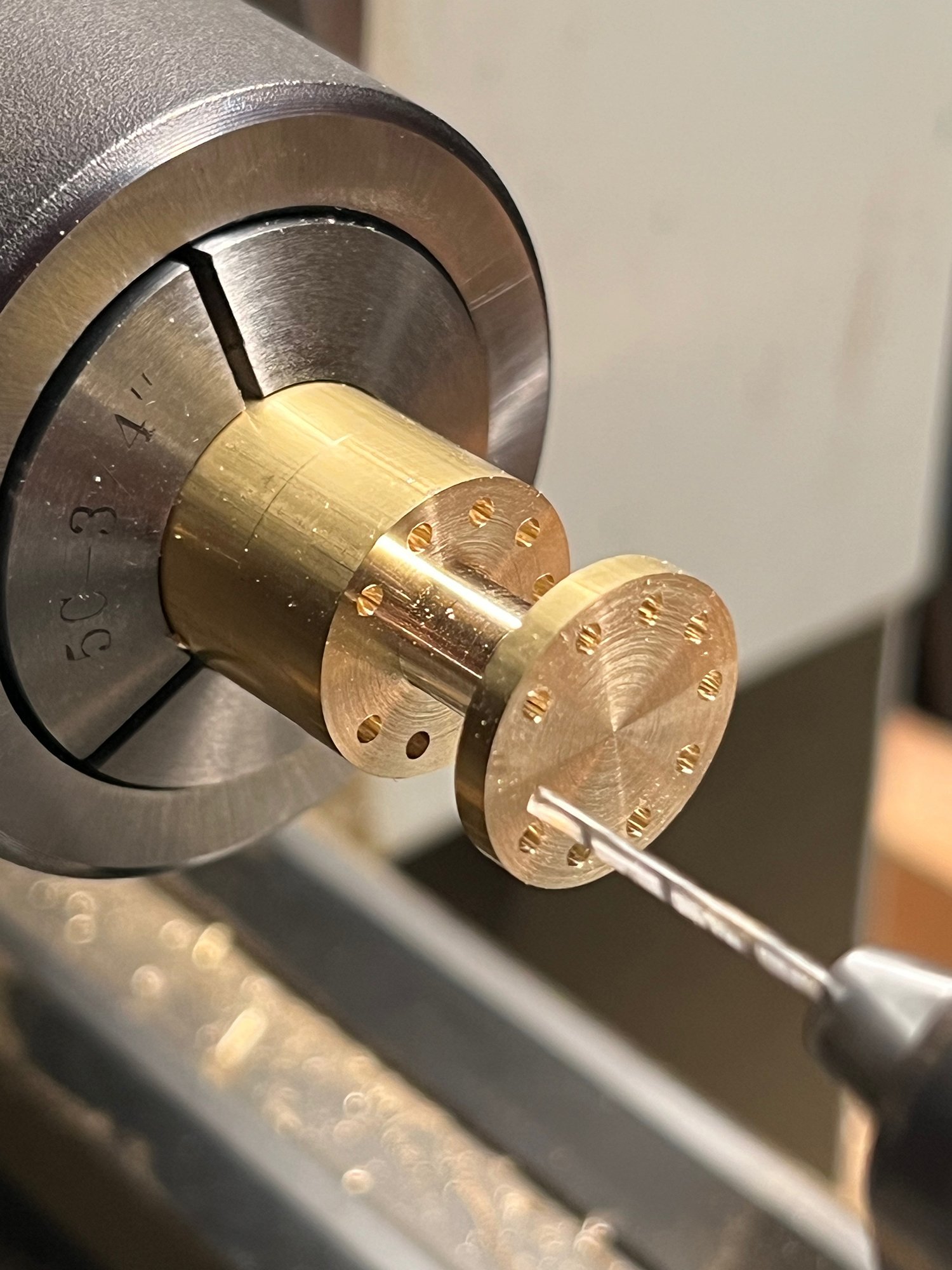

This piece shares a lot of DNA with “Perpetual No.1” but has some very notable upgrades. A moon dial was added, along with a day dial. It’s also a foot larger than “Perpetual No.1”, which may not sound like a lot, but that extra foot doubled the weight and gear size.

For anyone not familiar, a perpetual calendar complication keeps track of the date, including mechanically accounting for whether a month has 30 or 31 days, and even automatically adjusts for the 28 days in February, and 29 days in a leap year. The perpetual calendar mechanisms that I create switch instantly at midnight, so in the video, you can see the clock automatically click four full days when the hands pass 12:00 p.m.

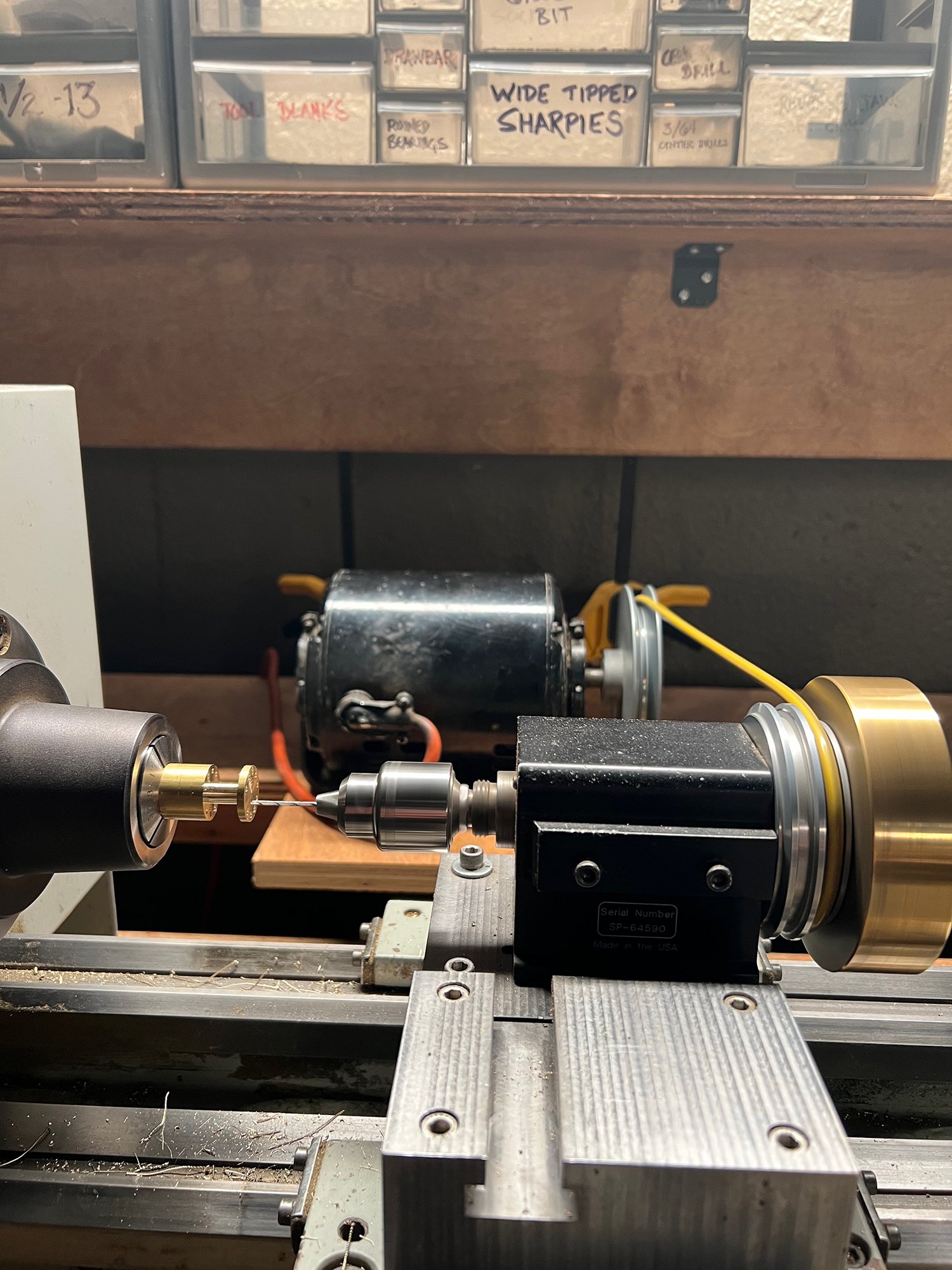

The moon dial has four different faces, and between those are constellations visible from the southern hemisphere. The large display for the four moons required a disc that took up almost all the space behind the perpetual calendar mechanisms. That means that all the mechanisms for the perpetual calendar had to be in front. Oftentimes, mechanical challenges and constraints can lead to aesthetic discoveries. This is one such case for me. The result of pushing all the mechanisms in front led to a large moon nestled above a forest of gears and levers, similar to the actual moon above a forest of trees.

There are a couple things to note about the main gears for this clock. The spokes are designed to mirror the overall design of the clock itself. Each spoke depicts the frame of the clock running down the middle, with the number-panels splayed out around it. Because of the size and the amount of detail, these gears also took significantly longer to sculpt than any others to date.

I’ll be delivering and installing this piece in the next months. While I’m looking forward to the trip, I’ll be sad to see this clock go.